HDRS Series Multi-segment Reaction Removal of hydrocarbons by catalytic technology

HDRS Series Multi-segment Reaction Removal of hydrocarbons by catalytic technology

- For hydrocarbon compounds (HC) in oxygen gas, we have launched CAC, MCAC and other oil removal and purification equipment, which can effectively deal with oil pollutants (C6+), so as to meet the oil-free demand of users for compressed air. However, for the users who require the total amount of hydrocarbons in the gas content, more difficult C1~5 hydrocarbons need to be further separated and treated. At present, more methods are used to obtain clean air source through cryogenic air separation, but it is difficult to separate hydrocarbon &nbs

- MESSAGE

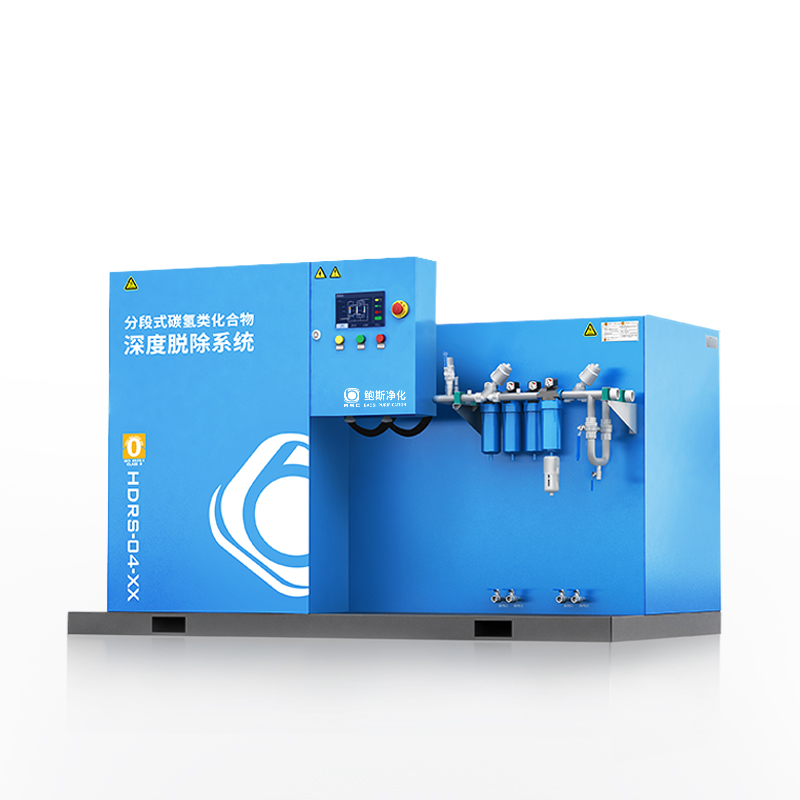

HDRS Series

Multi-segment Reaction Removal of hydrocarbons by catalytic technology

Working pressure: 0.6~1.58MpaG

Gas quality index:

C6+ Oil Pollutant content Class_0(GB/T13277.1-2008(eqv.ISO8573.1))

The hydrocarbon content of C1~5 reached ppb level, and the measurement values were referred to ISO8573.6

Product introduction

For hydrocarbon compounds (HC) in oxygen gas, we have launched CAC, MCAC and other oil removal and purification equipment, which can effectively deal with oil pollutants (C6+), so as to meet the oil-free demand of users for compressed air. However, for the users who require the total amount of hydrocarbons in the gas content, more difficult C1~5 hydrocarbons need to be further separated and treated. At present, more methods are used to obtain clean air source through cryogenic air separation, but it is difficult to separate hydrocarbon

Baosi Purification introduced the first compressed air segmented hydrocarbon depth removal process, system adopts catalytic oxidation technology, and independent research and development of catalyst as the core, for all hydrocarbon processing, can be the hydrocarbon content of oxygenated gas is reduced to the order of ppb, to provide users with the depth of clean compressed air.

Product features

The industry's first

Extreme cleanliness

Safe and stable system

Multi-segment Reaction Removal of hydrocarbons by catalytic technology

Independent research and development of core technology and materials

The hydrocarbon departs to the PPB level

Siemens complete control

Product advantages

The core of this technology is to use the segmented catalytic oxidation technology, in different temperature segments for different classes of hydrocarbons with different catalysts for treatment, clear goals, the reaction is more thorough,at the same time can greatly reduce the risk due to over temperature. The electrical part adopts Siemens control system for precise multi-point temperature control, and is equipped with a redundant interlock controller, to improve the stability and safety of the system operation, and effectively ensure the purification effect. The system has a process interface to convenient communication with DCS, SCADA and other local control systems. Meanwhile, equipped with remote Internet of Things module, the device can be monitored through mobile terminal or remote computer.

The normal service life of the catalyst of the equipment is more than 4 years. The equipment itself has no maintenance parts except for the particulate matter filter, and the use cost is low.