Class 0 oil-free air by catalytic technology

Class 0 oil-free air by catalytic technology

- TCAC series is a use of catalytic oxidation technology specially used for compressed air oil removal and sterilization equipment.

- MESSAGE

It is the efficient catalytic oxidation catalyst to make the oil-containing compressed air at a certain temperature, and the oil part produces the catalytic oxidation reaction under the action of the catalyst. It is completely converted into carbon dioxide and water, and at the same time, under the action of high temperature, the biological bacteria in the compressed air are killed, to achie

Third-generation of compressed air oil removal products: TCAC

Pressure range: 6~40 bar

Oil removal effect of compressed air: Class_0(GB/T13277.1-2008 (eq v.ISO8573.1))

Product introduction

TCAC series is an oil removal purification equipment developed based on catalytic oxidation technology. This technology is different from traditional filtration technology, which is not affected by ambient air quality, pressure, temperature, humidity and the life of consumables such as filter elements, and is widely used. The equipment adopts the integrated reaction design, the high-precision temperature control system, the compact structure, multiple protection, safe and reliable.

Sustainable delivery according to the GB/T13277.1-2008 (eq v. ISO8573.1) Oil-free compressed air with the highest purification grade of Class_0 as required by the standard.

The third generation of oil removal product upgrade features

1.System process optimization and upgrading

The overall system is more optimized with better performance

2.modular design

Modular design, good equipment expansibility and multi-component shunt treatment to ensure the uniformity of the air flow in the single reactor, improve the catalyst processing efficiency, and ensure the more stable operation of the equipment

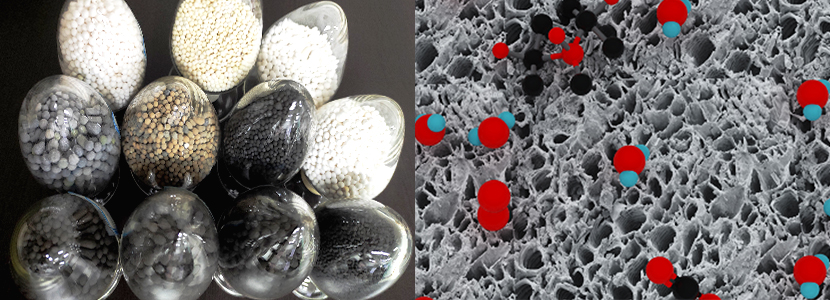

3.A new generation of catalyst

The independent research and development of the fourth generation of catalyst products, oil removal efficiency is higher, more reliable

4.Variable frequency operation can be realized

The lowest to 10% of the rated capacity of the equipment can be achieved

5.Front gas liquid separator

High-efficiency gas liquid separator is used to remove the foam rate in compressed air to more than 90%, effectively protecting the oil removal system

6.Non-stop maintenance

Single components can be repaired one by one to realize the whole machine non-stop maintenance

7.Internet of Things Module (optional)

It can realize online cloud control, saving time, effort and worry

8.Activated carbon bypass (optional)

The equipment can automatically switch the activated carbon filter (ACF component), eliminating the waiting time in the preheating stage of the equipment, and ensuring the continuous operation

Modularization + Frequency conversion

TCAC Series with a flow rate of more than 10m³ adopts modular design, which can realize adjustable control and non-stop maintenance.

Take the model TCAC-40 as an example: the TCAC-40 flow rate is 40m³, which is composed of four groups of 10m³ single modules (as shown below). If one of the groups needs maintenance, the other components can work normally.

.jpg)

Product advantages

Structural style

TCAC has three structural forms according to the flow rate

1.Flow rate of 1.5m³ structure form 1

2.Flow rate of 2.5m³, 4m³ structural form 2

3.Flow rate 6m³, 8m³, 10m³ structural form 3

4.Flow rate> 10m³ in structural form 4

Technical principles

TCAC uses a new generation of efficient catalytic oxidation catalyst independently developed and produced by Baosi Purification, so that the oil-containing compressed air at a certain temperature, and the oil and hydrocarbons under the catalytic oxidation reaction of the catalyst: CnHm + (n + m / 4) O2 nCO2 + m / 2H2O

During the operation of TCAC, C6+ hydrocarbons can be completely converted into CO2 and H2O. At the same time, under the action of high temperature, the biological bacteria in the compressed air are killed, realizing the oil removal and sterilization of the gas source, and obtaining the high clean grade compressed air. The whole process through high-precision temperature control, the system automatic adjustment, safe and stable.

Daily life, industrial production and automobile exhaust will produce oil pollutants, and the oil content in the atmospheric environment can not be ensured as less than the 0.01mg / m³ oil-free standard (i. e., national standard GB/T13277.1-2008 (eq v. ISO8573.1) Class 0 oil-free standard).

This product can not only remove the lubricating oil in the air compressor, but also remove the trace oil pollutants mixed in the atmospheric environment. It can provide continuous and stable oil-free compressed air with the class 0 oil-free standard according to GB/T13277.1-2008(eqv.ISO8573.1).

Industrial applications

TCAC Series can be widely used in biomedicine, electronics, food, textile, automobile, electricity and other industries with high requirements for compressed air quality. TCAC is an ideal solution for customers who intend to improve the quality of existing compressed air, especially in those cases where oil pollutants have an adverse impact on production.

Selection parameters

Recommended installation configuration

.jpg)